AI in Manufacturing: Smartening the Future of Production

On the other, waiting too long can cause the machine extensive wear and tear. Manufacturing plants, railroads and other heavy equipment users are increasingly turning to AI-based predictive maintenance (PdM) to anticipate servicing needs. While autonomous robots are programmed to repeatedly perform one specific task, cobots are capable of learning various tasks. They also can detect and avoid obstacles, and this agility and spatial awareness enables them to work alongside — and with — human workers.

Yet, successful implementation of AI in smart production necessitates complete automation equipment, management systems, and widespread sensor utilization. AI in business extends its transformative potential to the manufacturing sector, optimizing processes, driving efficiency, and fostering innovation. Back then, artificial intelligence was empowering robotics and automation to tackle mundane, repetitive tasks such as part-handling and sorting. Another key area of focus for AI in manufacturing is predictive maintenance.

Envisioning the Future Power of AI in Manufacturing

It can predict the changes in the output by changes in the temperature, equipment, raw materials, etc. Manufacturers can understand the differences and track the reason behind this change and make further decisions according to those changes. After all, if a human is required to have the final sign-off on a critical business process, they need to understand what they are signing. That means the results need to be presented in a way that is easily intelligible.

Once the AI software is trained, it can be used to inspect new car parts and identify any defects. For example, imagine a clothing retailer utilizing AI-based forecasting to predict the demand for various garments. By leveraging historical sales data and external factors such as weather forecasts, the retailer can adjust their inventory levels accordingly, minimizing stockouts and overstock situations. Probably, the best word to define Industry 4.0 would be digitalization as here resources, information, and humans are connected with the help of modern digital systems.

AI in predictive maintenance

The COVID-19 pandemic also increased the interest of manufacturers in AI applications. As seen on Google Trends graph below, the panic due to lockdowns may have forced manufacturers to shift their focus to artificial intelligence. Collaborative robots — also called cobots — frequently work alongside human workers, functioning as an extra set of hands.

This results in improved resource utilization, reduced lead times, and enhanced customer satisfaction. Manufacturers leverage AI technology to identify potential downtime and accidents by analyzing sensor data. AI systems help manufacturers forecast when or if functional equipment will fail so its maintenance and repair can be scheduled before the failure occurs.

Data collection and analysis are already being used in many industries to predict consumer behavior and generate highly personalized communications to customers or potential customers. A recent study at Indiana University found that machine learning algorithms could even accurately analyze Twitter feeds to scan public sentiment and determine stock market movements. A leading European energy company wanted to take its manufacturing process from reactive to proactive with predictive maintenance. The reliability of systems in the plant is critical for many reasons, from being able to manage maintenance costs to better managing safety and environmental concerns. Specifically, AI-based applications can replace camera portals with automated image recognition systems, view images of auto production, and compare them to a database of hundreds of other photos. With automated image recognition, production deviations are detected in real-time and corrected before they pose a more significant problem.

AI in manufacturing for predictive maintenance is becoming increasingly popular in the manufacturing industry. An Electrical and Electronics Engineers survey found that 82% of manufacturers use or plan to use AI for predictive maintenance. This indicates a strong trend toward adopting this technology in the industry. To be competitive in the future, SMMs must begin implementing advanced manufacturing technologies today.

The Potential of AI to Transform the Future of Manufacturing Industry

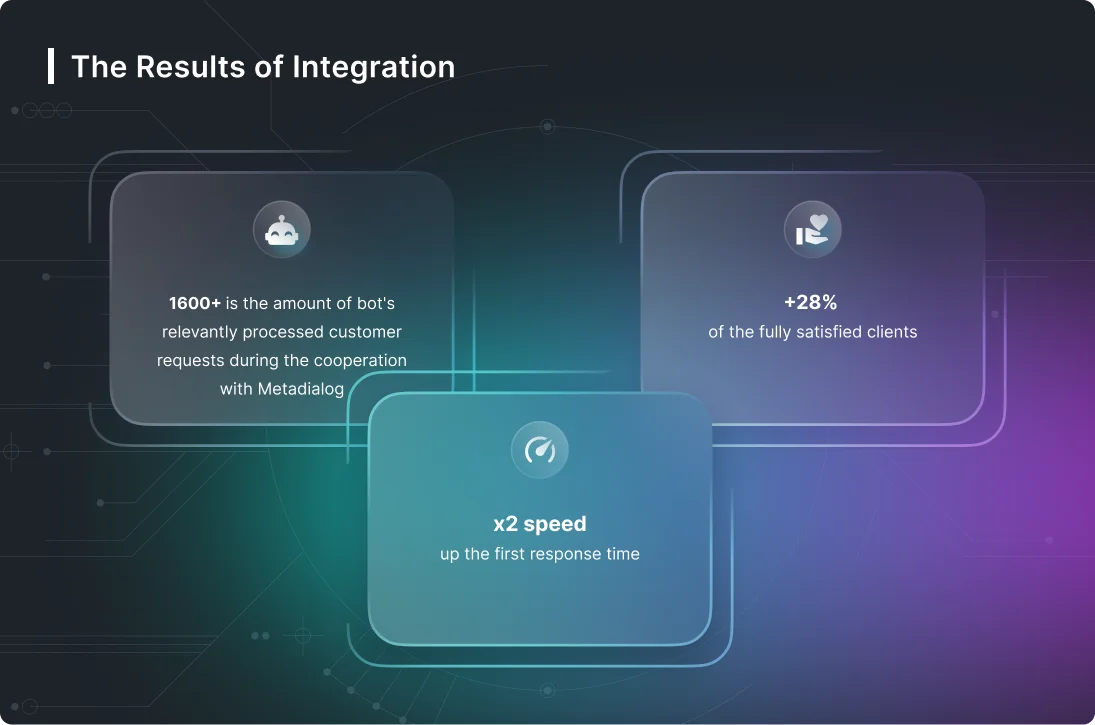

Read more about https://www.metadialog.com/ here.

- In this exploration of AI in manufacturing, we will dive deep into how these applications are reshaping the industry.

- With this, Toyota made its manufacturing operations safer, better in quality, and more efficient.

- Therefore, we are likely to see an upsurge in AI-based technologies in manufacturing along with the advent of new high-pay jobs in this arena.

- With a background that includes experience at EY and Wipro, she’s been a trusted advisor for clients seeking innovative solutions.

- AI is assisting in the design of products, but fabrication is still in the early stages of AI adoption.